In the School of Mechanical, Aerospace & Civil Engineering, the group of Dr. Robert Prosser is collaborating with Unilever who are interested in in-silico evaluation and simulation of their manufacturing processes in order to accelerate the introduction of new and better products into the market.

To tackle this business challenge, Dr. Prosser’s group have been using UoM Research IT High Performance Computing (HPC) facilities (the CSF) and the Hartree Centre at STFC Daresbury, to perform multiphysics numerical simulations of mixing processes typically encountered during the manufacture of emulsion based formulated food and personal-care products eg shampoo. Properties such as viscosity and droplet size are sensitive to the mixing process and determines the shelf-life and consumer appeal in terms of texture and even mouthfeel of the final product.

Computational fluid dynamics (CFD) is used to simulate the complex flow and mixing patterns and is coupled to particle transport and rheology (deformation and flow) to characterise the evolution of the underlying microstructure of the processed fluids. Ioannis Bagkeris, supported by an iCASE PhD studentship, is using the CSF to accelerate the parameterisation and testing of improved droplet dynamics and breakup models in pilot-plant scale static mixing simulations. His work will result in the development of theoretically sound and robust correlative predictions between final product drop sizes and mixer operating parameters.

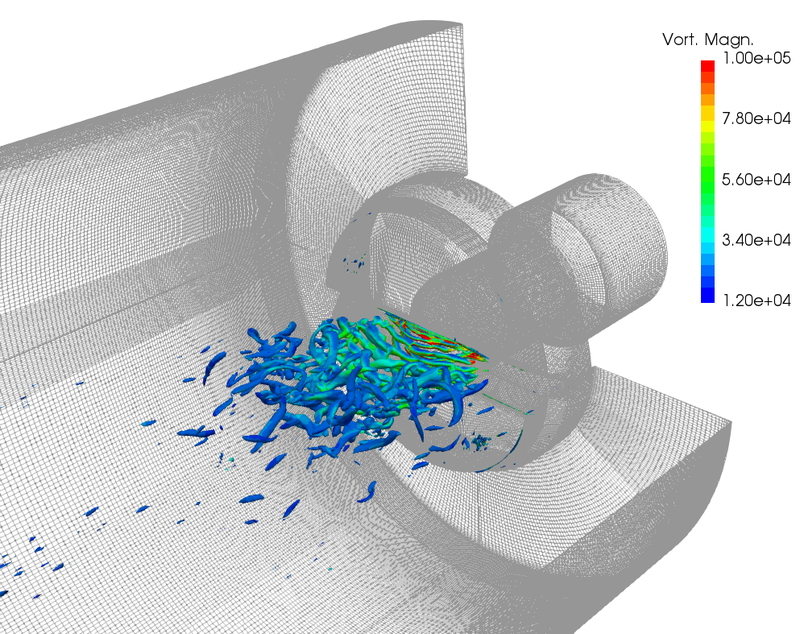

The contours in the figures (top: rotor-stator mixer, above: static mixer) show vortical structures, highlighting the regions where the processed fluid experiences extensive rotation and intense mixing.

Dr. Vipin Michael, who is working on an Innovate UK project, has used the CSF to simulate the processing of highly viscous dense emulsions in high speed rotor-stator mixers. Technical challenges in these projects arise due to the requirements for highly refined computational grids to model the complex geometry, and for sufficiently time and space resolved simulations to capture the essential flow dynamics. HPC machines at CSF and Hartree Centre are used as these computational requirements are beyond the capabilities of desktop processors. Typical jobs range from 96 to 384 MPI ranks and 24-72 hours wall clock time, depending on the grid size and the complexity of the underlying physics. The Code-Saturne open source CFD software developed by EDF is used for the computational simulations as it is highly scalable and is well maintained and supported on the CSF by the Research IT team.

The group is looking forward to the new enhanced increase and updates in computational power of the local CSF, to continue collaborating with Unilever on future projects. These projects involve increasingly refined temporal and spatial resolution in order to tackle more complex fluid physics such as bubble cavitation, statistically inhomogeneous turbulence, and viscoelastic flow instabilities.

HPC resources are essential in making simulations of such industrial mixing processes computationally tractable. These simulations allow process engineers to optimize their process designs, better predict final product properties across scales and reduce reliance on pilot-scale experiments. This in turn leads to process intensification, waste reduction and potential cost savings for Unilever.

If you are interested in using the computational resources provided by Research IT or external partners, please see our website or get in touch.